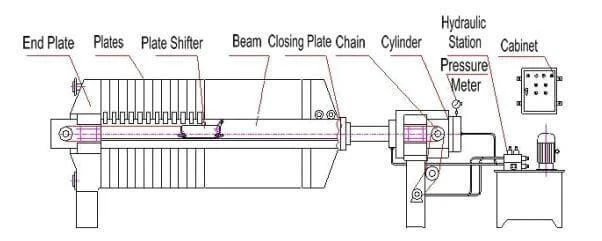

There are 2 types of Cylinders (1) Lock nut type (2) Chrome plate types,

(If the cylinder is of Chrome Plated Type then there will be a small Electric Panel with it)

Filter Press Specifications

| Structures | Cast Iron/Mild Steel/Stainless Steel/ Aluminum. |

| Nozzles | PP/MSPP/SS 304/SS 316 |

| Delivery | Open/Closed/Open cum Closed Type. |

| Washing Types | Wash/Non- Wash. |

| Working Pressure | Up to 20 kg/cm sq. |

| Working Temp.-P.P. | 85 C or more on require. |

| Filter Media | P.P./Nylon/Cotton or as per requirement. |

| Plate size | Design | Plate Thickness | Cake Thickness | FA(m2) Function Area Per Plate | Cake Hold. C(LR>) | M.p.ce hole (Middle Plate Center Hole) | Checnknut Size | |

| 300 X 300 mm sq. | 12" | CERAMIC | 50 | 30 | 0.15 | 1 | 49 | 20 |

| CHEMICAL | 0.15 | 1 | ||||||

| 355 X 355 mm sq. | 14" | CERAMIC | ||||||

| CHEMICAL | ||||||||

| 470 X 470 mm sq. | 18" | CERAMIC | 55 | 35 | 0.25 | 5 | 63 | 65 |

| CHEMICAL | 0.25 | 5 | ||||||

| 610 X 610 mm sq. | 24" | CERAMIC | 60 | 38 | 0.5 | 10 | 76 | 76 |

| CHEMICAL | 0.5 | 10 | ||||||

| 630 X 630 mm sq. | 25" | CERAMIC | ||||||

| CHEMICAL | ||||||||

| 750 X 750 mm sq. | 30" | CERAMIC | 60 | 38 | 0.7 | 15 | 87 | 87 |

| CHEMICAL | 0.8 | 15 | ||||||

| 800 X 800 mm sq. | 32" | CERAMIC | 65 | 40 | 0.9 | 18 | 87 | 100 |

| CHEMICAL | 0.9 | 18 | ||||||

| 915 X 915 mm sq. | 36" | CERAMIC | 65/72 | 40/47 | 1.2 | 25/28 | 100 | 100 |

| CHEMICAL | 1.2 | 22/28 | ||||||

| 1000 X 1000 mm sq. | 40" | CERAMIC | 70 | 40 | 1.6 | 28 | 100 | 100 |

| CHEMICAL | 1.6 | 30 | ||||||

| 1100 X 1100 mm sq. | 44" | CERAMIC | 70 | 40 | 1.9 | 38 | 100 | 100 |

| CHEMICAL | 1.9 | 39 | ||||||

| 1200 X 1200 mm sq. | 48" | CERAMIC | 70 | 40 | 2.3 | 44 | 100 | 100 |

| CHEMICAL | 2.3 | 42 | ||||||

| 1500 X 1500 mm sq. | 60" | CERAMIC | 75 | 40 | 3.6 | 70 | 150/175 | |

| CHEMICAL | 3.6 | 70 | ||||||

| 800 DIA. mm sq. | 32" (ROUND) | CERAMIC | ||||||

| CHEMICAL | ||||||||

| 600 DIA. mm sq. | 24" (ROUND) | CERAMIC | ||||||

| CHEMICAL | ||||||||

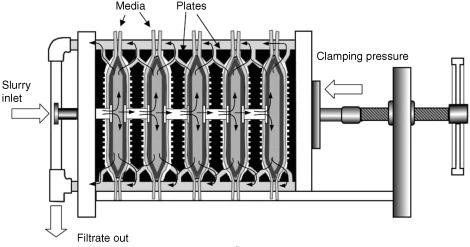

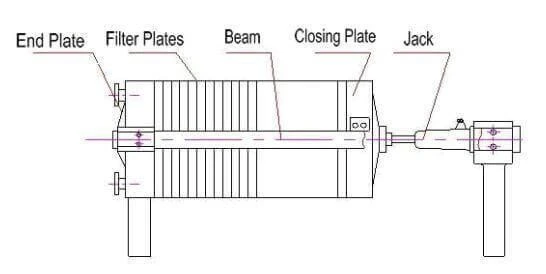

(Hydraulic Plate & Frame Filter Press has been used for many years in the dewatering industries, and is widely used in sludge dewatering. The plates and frames of this type of press are arranged alternately in parallel, and the filter cloth is clamped between each filter plate and filter frame. When this filter press is used for sludge treatment, the plates and the frames are compacted using a hydraulic cylinder, and when compacted, the press will form a filter chamber between the filter plate and the filter frame. Sludge will be pumped in through the inlet flange, and filtrate will discharge thought the filtrate holes in the filter plates, the filter cake will build up in the filter frame and filter through the cloth on the filter plate, the filter cake is easy to discharge after loosening the impacted plate and frame. The Hydraulic Plate and Frame Filter Press has the advantages of simple operation, and a high solids capability)

(Hydraulic Filter Press is made up of two recessed chamber plates. Slurry is pumped into the press by the feed pump, the suspension is pumped into each filter chamber and the solids are collected in the chamber on the filter cloth, while the filtrate passes through filter cloth and flows along the filter plate recesses to the discharge channel. When the filtration is complete, washing water can be introduced to wash the filter cake. After washing, compressed air can be introduced to blow the remaining wash liquid out through the filter cloth. Cake discharge can now take place by opening the filter plates, and the cake will discharge generally by gravity. The cakes are stored in filter chamber between the two filter plates)

(Hydraulic Membrane Filter Press is very similar to the Chamber Filter Press but adopts an inflatable Membrane on one side of the filter plates, which when inflated to high pressure squeezes the filtered cake reducing the moisture content of the cake even more. The squeezing medium can be air squeeze (compressed air /N2), or liquid squeezing (water or other medium), it depends on the process. We can customize this for food grade Filter Presses. The controls for the system are usually Human-Machine Interface HMI and PLC controlled)

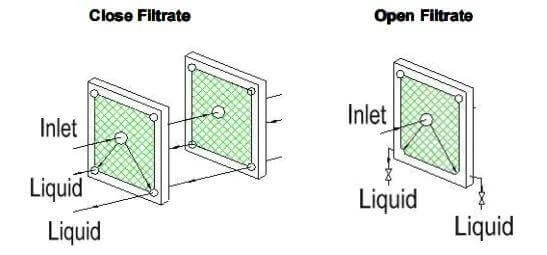

Close filtrate: filtered liquid is discharged via the pipe, which is consisted of the outlet of all plates. It is mainly used for special slurries, such as toxic, volatile, etc.,

Open filtrate: filtered liquid is discharged via the outlet on every plate. The open filtrate is widely used because if the filter cloth is damaged, it can directly find the problem soon. (If the filter cloth is broken, the liquid will be not clean. Please turn off the tap and repair the cloth after discharge.