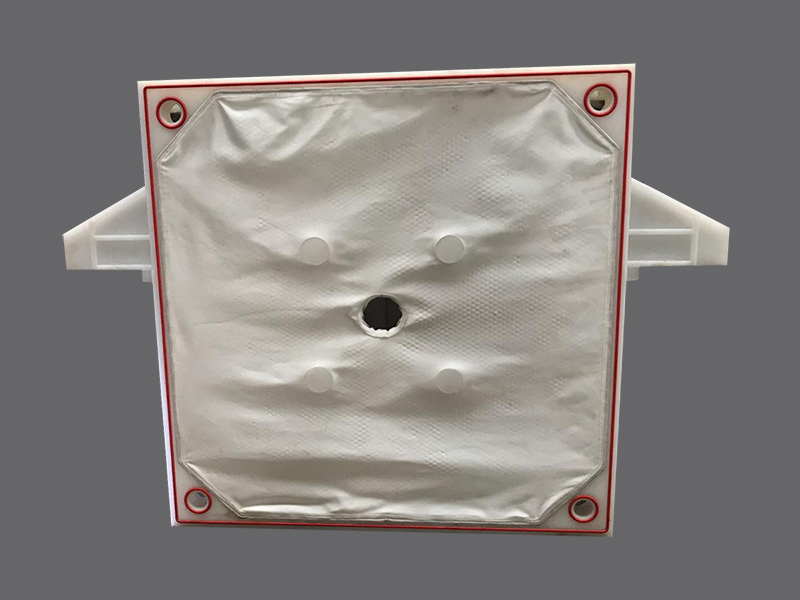

The recessed chamber filter plate made from polypropylene is a development of the plate and frame filter plate and has the same functionality.

The chamber plate frame is however integrated within the chamber filter plate thus significantly enhancing the plate's stability. This enables chamber filter plates to be used at much higher filtration pressure levels. Optional cake and plate thicknesses are available depending on the specific filtration conditions and application. Amar Plastics chamber filter plates can also be supplied in caulked and gasketed design (CGR). The chamber filter plates are made of plastic and feature excellent chemical resistance and simple handling.

The design and manufacturing method for the HR gives a low-cost alternative to standard chamber filter plates. It is available in sizes 470mm, 500mm, 630mm, 800mm and 1000mm, and up to a maximum filter cake thickness size of 32mm.

| Format | Standard sizes: 250, 400, 470, 500, 630, 800, 915, 1000, 1067, 1200, 1300, 1450, 1470, 1500, 1500 x 2000 und 2000 x 2000 mm. These formats are available in open and closed designs. Larger and alternative formats available upon request. |

| Feed eye position | Standard feeds: Centralised feed, decentralised feed, corner feed, external feed, position eye In general, any feed eye design is possible and can be made according to customer requirements. |

| Pressure | Standard products are suitable for a maximum filtration pressure of 8 or 16 bar depending on the product. Special products for pressure levels of 30 bar and higher are available. |

| Temperatures | Maximum permissible filtration temperatures depend, among other things, on filtration pressures, chemical composition of the slurry to be filtered, cycle times and choice of material. |

| Materials | Amar Plastics chamber filter plates are available in the following materials according to intended use:

|

In a conventional chamber filter press, filter cake is formed in layers until the chamber is full with solid matter. As the filter cake forms, its permeability and flow rate decrease as the solid content increases within the chamber and the cake becomes increasingly drier.

Compressible products reduce cake permeability to a disproportionate degree, which can lead to longer filtration cycles and thus higher operating costs. Inefficient filtration cycle times can be avoided by using membrane filter plates.